AI-Driven Cylinder Scanning System and Auto-Approval System

Executive Summary

XYZ Company, a prominent distributor of refrigeration gases and air conditioning products in the U.K. for over 20 years, has always prioritized environmental safety. However, the company faced challenges in the manual verification and approval of gas cylinders—both during transactions and when they returned to the warehouse in an empty state. This process was not only time-consuming but also prone to errors.

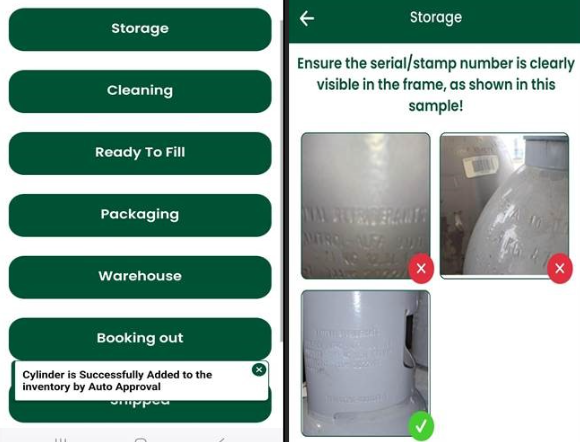

To address these issues, XYZ implemented an AI-powered system to extract text from cylinder barcode labels, identify each cylinder's stage, and automate the approval process. Integrated into XYZ's mobile application, this AI-driven solution significantly reduced manual intervention, enhanced operational efficiency, and ensured accurate data processing, improving overall effectiveness.

Problems faced by Client:

Before implementing the AI-driven system through a mobile app, XYZ relied on a manual verification and approval process to track cylinders. All work was done manually by operators at the warehouse, who were required to make individual entries into the system for each cylinder. The staff faced challenges in maintaining accurate records, particularly in identifying the stage of each cylinder, such as cleaning, refilling, emptying, warehouse, available, or consumed. This manual process made it difficult to manage and collect empty cylinders efficiently.

This posed several challenges:

High Labor Costs & Inefficiency: Supervisors manually checked and approved each cylinder, consuming valuable time and resources.

Risk of Human Error: Manually entering and verifying metadata, including serial numbers and return codes, increases the likelihood of mistakes, leading to record discrepancies.

Delays in Processing: The time-consuming nature of manual approvals caused workflow bottlenecks, reducing overall operational efficiency and slowing down cylinder tracking.

Lack of Centralized Data Tracking: Operators struggled to efficiently manage and collect empty cylinders without an automated system, making it difficult for supervisors to monitor the overall cylinder lifecycle.

Proposed Solutions:

We developed and integrated an AI-powered system that streamlines the entire verification and approval process to address these inefficiencies. The system utilizes advanced AI algorithms to extract and validate metadata from cylinder images captured within the XYZ mobile application.

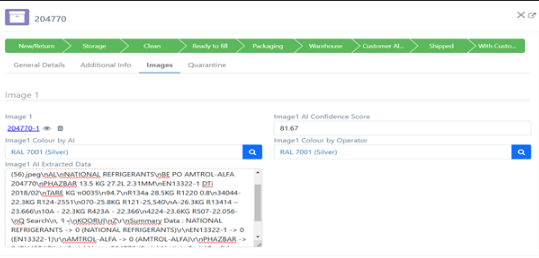

• When a cylinder image is uploaded, the AI model processes the text and identifies key metadata elements such as Serial Number, Product Code, Return Code, and Cylinder Colour.

• The system assigns a confidence score to assess the accuracy of the extracted information.

• If the confidence score meets a predefined threshold and the extracted metadata matches Asset Track data, the system automatically approves the cylinder, reducing manual intervention by operators and supervisors.

• The extracted metadata, confidence score, and detected cylinder colour are securely stored for audit tracking and future reference.

Key Features

AI-Driven Text Extraction: The system extracts text details from images of cylinder labels captured from the application, eliminating warehouse operators' manual entry into the system.

Metadata Identification: The AI algorithms analyze extracted text and identify critical metadata such as Serial Number, Product Code, Return Code, and Cylinder Colour.

Confidence Score Calculation: To ensure reliability, the system assigns a confidence score to the extracted metadata, helping supervisors determine its accuracy.

Automated Approval Process: If the extracted metadata aligns with Asset Track data and meets the confidence threshold, the system automatically approves the cylinder, reducing approval time.

Data Storage & Security: The extracted data, confidence scores, and detected cylinder colors are securely stored within the system for tracking and auditing purposes.

Technologies Used

• DotNetNuke

• HTML, CSS, Java Script

• React-Native (For developing mobile app)

Mobile App

Website

Client Benefits:

The AI-driven system significantly improved operational efficiency at XYZ by:

Minimized User Intervention: The system reduces manual workload for operators and supervisors, allowing them to focus on more strategic tasks.

Enhanced System Efficiency: Automating the verification process significantly reduces processing time and labor costs.

Improved Accuracy: AI-driven validation ensures a higher level of precision, minimizing errors commonly associated with manual data entry.

Centralized Data Tracking: Extracted data and metadata are securely stored, providing easy access for audits and future reference.

Scalability & Adaptability: The solution is designed to handle large volumes of cylinder data, making it scalable for future growth and expansion

Faster Decision-Making: By automating the approval process, cylinders are processed and approved in real time, improving overall workflow efficiency.

Real-time tracking: Real-time monitoring of cylinders at different stages (New/Return, Storage, Cleaning, Ready to Fill, Packaging, Warehouse, Customer Allocation, With Customer, etc.).

By implementing this AI-powered solution, XYZ Company successfully optimized its cylinder tracking and approval system, reducing errors, increasing efficiency, and allowing supervisors to focus on more strategic tasks. This transformation highlights the power of AI in streamlining industrial operations and ensuring accurate, automated decision-making.